This year I’m participating in monthly DIY Challenges with a wonderful group of DIY bloggers. This month’s them is DIY Home Improvement, and today I have one of my favorite projects from my latest boy bedroom makeover – a faux shiplap wall. Don’t forget to check out all the other great projects linked at the bottom of this post!

When I started renovating Weston’s room, I was really excited to try my hand at some sort of accent wall. I’ve seen a lot of modern wood pattern accent walls lately, but his room is so small and I was worried something like that might overwhelm the space. So I settled for a more traditional shiplap wall inspired by Table and Hearth. There are a hundred different ways to do shiplap, and all the tutorials online can get a little overwhelming. So I’ll just tell you ahead of time – I used this method because it was the absolute cheapest way to get that shiplap look.

This post may contain affiliate links. If you make a purchase from one of the links, I may make a small commission at NO EXTRA COST to you. This helps keep the tutorials and plans free here at Bitterroot DIY. Thank you for your support! See my full disclosure here.

In case you missed it, I also shared the plans for each piece of furniture in his room – the Twin Bed, Dresser, and Toy Organizer.

- 4′ x 8′ sheets of Eucaboard

- Lattice Trim

- Miter Saw

- Jigsaw

- Circular Saw (or table saw)

- Finish Nailer

- 1 1/4″ Finish Nails

- Stud Finder

- Level

- Tape Measure

- Pencil

- Safety Glasses

- Respirator

- Respirator Filters

- Ear Protection

I’ve seen quite a few people use 1/4″ plywood for a shiplap wall, which works great. I decided to use sheets of Eucaboard from Home Depot to save a little extra money. At $6.50 per board, they’re about half the price of 1/4″ plywood and give the same result.

We live in Minnesota, so the humidity wreaks havoc on the house, especially with the big temperature swings. The house is constantly expanding and contracting, as well as all the trim and wall treatments. Since eucaboard expands and contracts more than plywood, I left about 1/2″ gap between the perpendicular walls and the start of each board to allow for expansion. The lattice trim covered it up. If you don’t leave a gap for expansion, the boards may bubble off the wall.

Measure your wall to determine the number of sheets of Eucaboard and lattice trim that you’ll need. For my 8′ x 12′ wall, I used three sheets of 4′ x 8′ Eucaboard and four 8′ pieces of lattice.

To calculate the number of sheets for 6″ strips:

- Calculate the square feet of wall and multiply it by 12.

- Divide the result from #1 by the width of boards you want to use to find the total linear feet.

- Divide the total linear feet by 8 (the length of one sheet).

- Divide the result from #3 by 8 (total number of 6″ strips from one 4′ x 8′ sheet).

*** this calculation is different for widths other than 6″ ***

Step 1.

Rip the eucaboard into 6″ strips with a circular saw or table saw. You can do a different thickness, but 6″ divides a 4′ x 8′ sheet equally into 8 strips. The last strip will be slightly less than 6″ due to the width of the saw blade, but I just saved those pieces for the bottom row and covered them with the baseboard trim. If you want to use a different thickness, you may have to grab a few extra sheets of eucaboard.

Step 2.

Once you’ve marked the studs along your wall, begin installing the shiplap planks from top to bottom. Since ceilings are not always perfectly level, position the first plank as close to the ceiling as possible and then use a level to make sure it is level. If you have to adjust the plank down from the ceiling in a few parts, that’s fine – the lattice trim will cover it up later. The goal is to get that first row perfectly level so the rest of the planks are level! Don’t forget to leave a gap between the board and perpendicular wall to allow for expansion (I did 1/2″). Once you’ve positioned the plank, attach it to the studs with 1 1/4″ finish nails.

Start on one side of the wall and work your way across. I worked right to left since I like to read backwards …

JK. JK. I have no idea why I went right to left, but here we are haha. The important part is to stay consistent for the whole wall.

To ensure evenly spaced vertical joints, start with a full length board. Once you can no longer fit a full length board, cut a board to length to finish that row. Start the next row with the rest of the piece that you cut the last board from. Again, make sure to work from right to left (or left to right) for the whole project. Working the same direction and using the last piece you cut staggers the vertical joints perfectly.

I used paint sticks to space the rows 1/8″ apart. You can use tile spacers, playing cards, a speed square, etc.

Step 3.

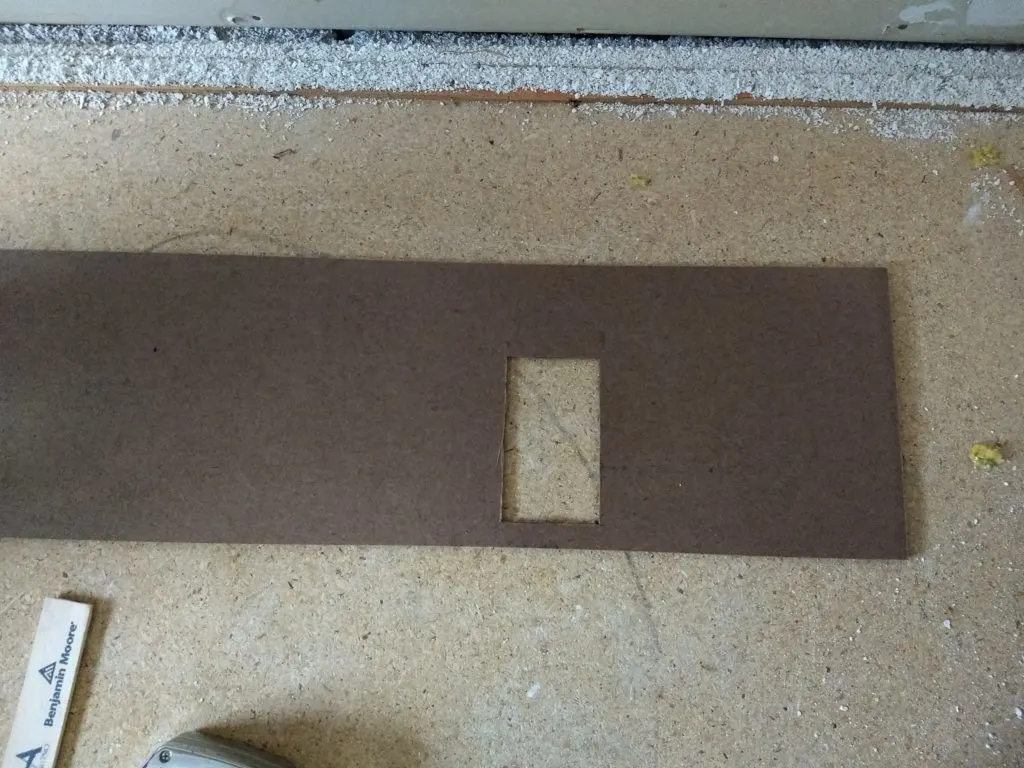

To work around outlets and/or switches, measure the opening horizontally and vertically.

Transfer your measurements onto the shiplap plank.

Cut the opening out with a jigsaw and install the plank.

Work your way along the wall until it’s all covered.

Step 4.

Once you’ve installed all the shiplap, prime it. I used my favorite Bullseye 123 primer.

Start by cutting in all the seams and edges with a brush. I just used a 1 1/2″ angle brush and it worked great to get in all the nooks and crannies.

Then finish it up with a paint roller and let it dry.

Primer is some pretty potent stuff, so I always make sure to wear a respirator … especially when I’m working in a closed room in the house. I have this respirator and filters from 3M and have been really happy with it. I use it for painting, staining, sanding, etc.

Step 5.

Time to paint! Repeat the same process as you did with the primer. Start by cutting in all the seams with a brush, and then use a roller for the rest of the wall. The color is Benjamin Moore “Steel Wool”.

If you own a paint sprayer, by all means use the paint sprayer!

Step 6.

Last but not least – trim the sides, top, and bottom of the wall.

Simply measure your wall, cut the lattice trim to length, and attach with 1 1/4″ finish nails.

I used 3/4″ pre-primed MDF for the baseboard trim around the whole room.

To finish things up, re-install any switch and/or outlet covers. And there you have it!

Please let me know if you have any questions and I’ll get back to you as soon as possible!

| Tylynn |

Thanks for stopping by!

For more project ideas, you can find me on Pinterest. And to stay up to date with the latest shenanigans, follow me on Instagram.

Stacy

Thursday 6th of May 2021

I love the steel wool color. Was wondering what color the other walls are?

tylynn_sattler

Monday 10th of May 2021

Thanks. The other walls are Benjamin Moore pale oak

Alicia Hursley

Thursday 25th of March 2021

I can't wait to throw some shiplap up on my walls! We just bought a fixer-upper and we definitely need to take care of the older-looking walls. As soon as that's done we just need to do a hardwood floor refinishing and a few kitchen updates to put it up on the market. Thanks for sharing.

Leslie

Saturday 23rd of January 2021

I’m in the middle of this project and just wondering is it really necessary to prime? I’m painting a dark colour

tylynn_sattler

Monday 25th of January 2021

Yes I'd recommend priming so the paint adheres really well.

Judy

Monday 24th of August 2020

Great diy I can’t wait to try myself! And this weekend is my target date. I live in the hot, humid south... Georgia... and your comments about the board swelling scare me a little. I am curious if the boards have noticeably expanded on your walls. After corners are caulked in have you seen any major issues with expansion and contraction. Thank you for your detailed instructions. Your project is a great inspiration!

tylynn_sattler

Monday 31st of August 2020

Thanks Judy!

Yes, the boards expand and contract significantly with the humidity changes in Minnesota. I left gaps between the ends of the boards and the wall so they can move as necessary (about 1/2" gaps, so pretty substantial). I covered the ends with a piece of trim so you can't see the gap. I did not use any caulk.

It seems to be doing pretty well so far!

Anaka

Tuesday 18th of August 2020

I’ve had some sleepless nights over a really unsightly ceiling and was wondering if you think this could work based on your experience. I’m not set on the shiplap look or the coffered ceiling one, but those two solutions seem to be the most doable. The ceiling does have plywood on it covered with some insulation and that’s what I need to pretty up. What do you think? Would it be doable?

tylynn_sattler

Saturday 22nd of August 2020

Yes, shiplap ceilings look great. However, I'd recommend going with actual tongue and groove for a ceiling cus it will look more finished. Just ask for tongue and groove at the hardware store (Home Depot or wherever) and they'll direct you to it. It's a little more expensive, but worth it for a ceiling where it'll be more permanent.